News

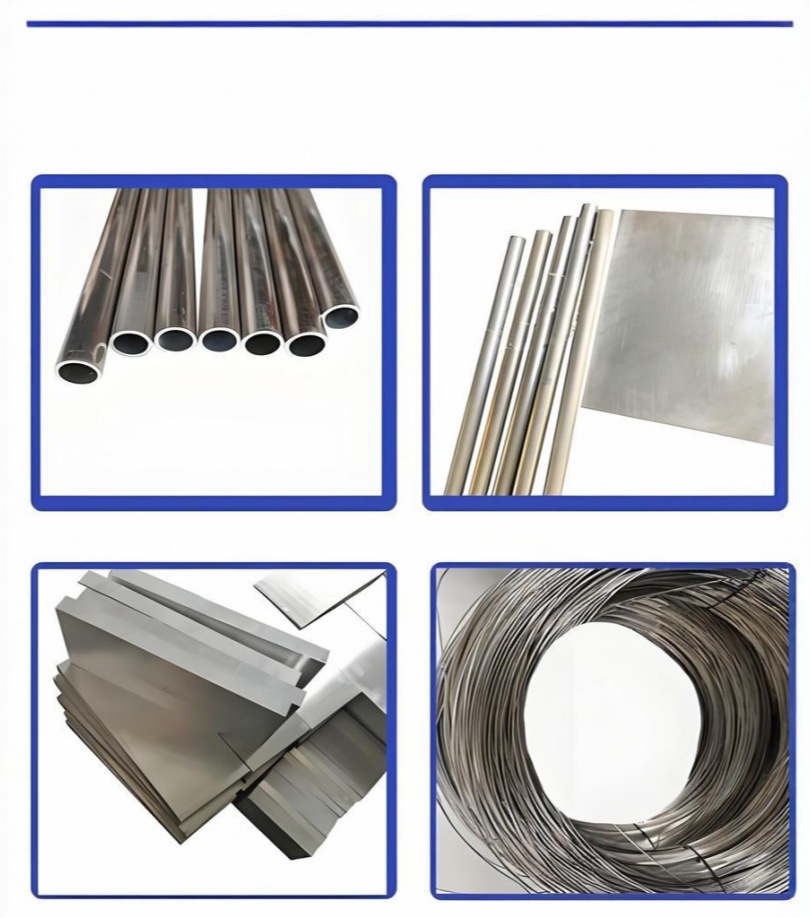

Brief discussion on the research status of Ho-containing magnesium alloys

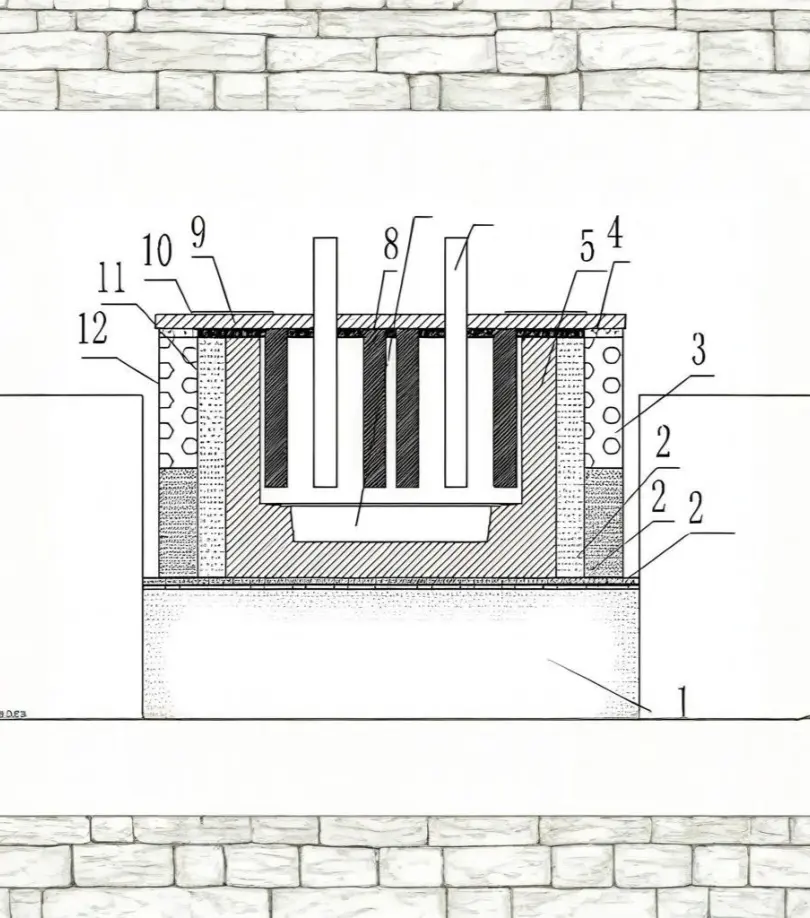

As the lightest metal structural material in practical applications, magnesium alloy has the advantages of high specific strength, specific stiffness, good electromagnetic shielding and dimensional stability, and no pollution. Commonly used commercial magnesium alloys have good formability and room temperature strength, but their heat resistance is still poor. Therefore, it is necessary to develop high-strength and heat-resistant magnesium alloys to meet the needs of different usage environments.

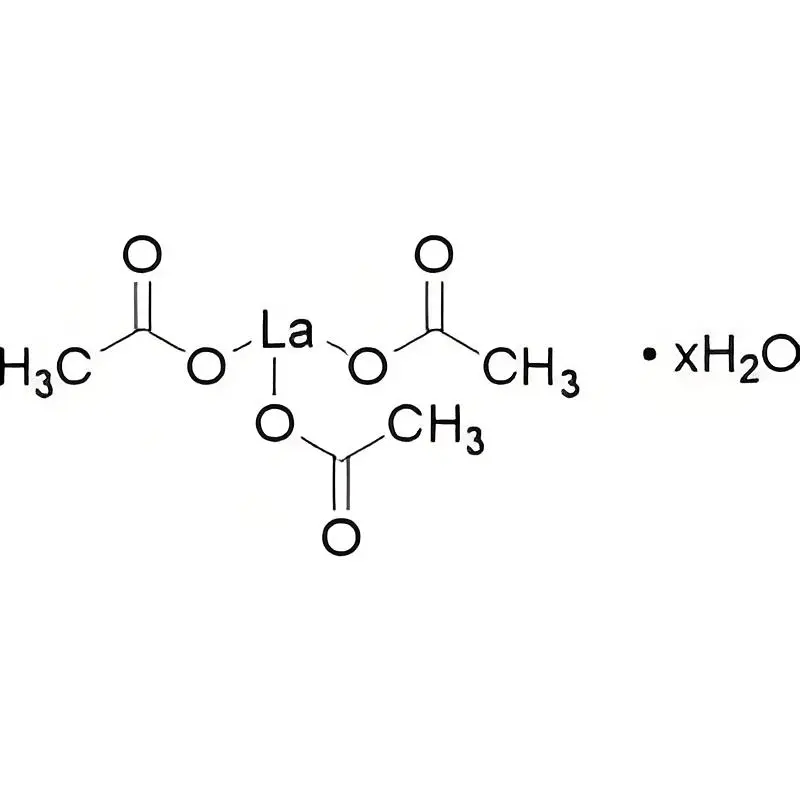

Application and research progress of rare earth acetate

Rare Earth acetate is widely used in catalysis, corrosion inhibition, luminescence, batteries and medicine, showing huge development space. Rare earth acetate crystals will not get wet and stick in the air, and have excellent water solubility and good thermal stability. With the deepening of research on rare earth acetate, rare earth acetate will play a more important role in the field of industrial materials.

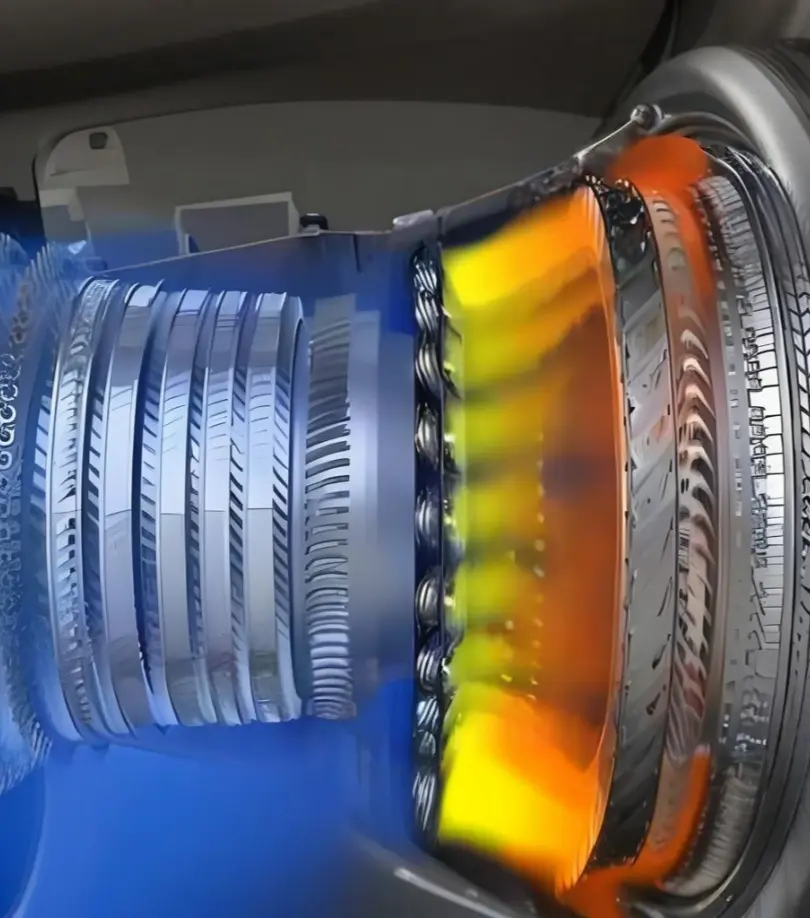

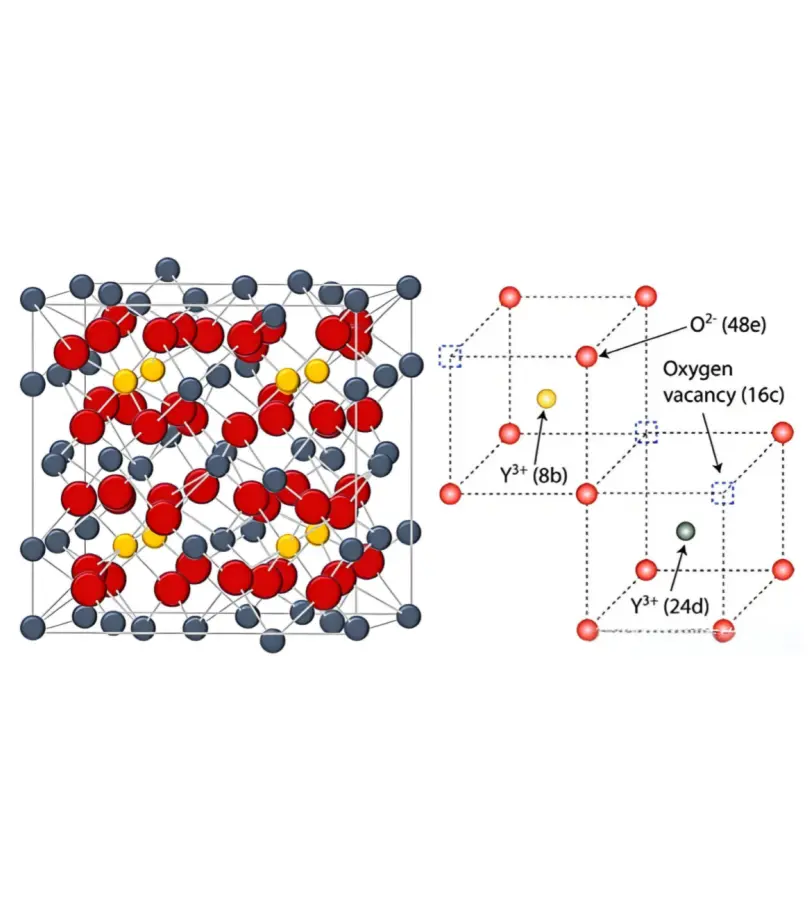

Application of new rare earth materials in the field of new energy technology

As functional modified materials, rare earth elements play a key role in many links of the new energy industry. The innovative development of new rare earth materials is of great significance for improving the production conversion efficiency of new energy, optimizing storage and transmission efficiency, and serving new energy terminal equipment.

Since modern times, mankind has experienced three industrial revolutions, the essence of which is the innovation of energy and materials. The emergence of intelligent equipment driven by artificial intelligence technology has turned the driving force into green renewable energy, greatly liberating human productivity, which also indicates that the "intelligent" era is coming. This energy revolution will bring about all-round innovation in energy production, energy storage, energy transmission and energy terminal use.

A brief discussion on the research and application progress of SmFeN permanent magnet materials

Samarium iron nitride (SmFeN) rare earth permanent magnet material is a new generation of rare earth permanent magnet material. It is mainly composed of rare earth element samarium (Sm) and transition metal iron (Fe), and nitrogen (N) element is introduced through nitriding process to form a compound with a specific crystal structure and excellent magnetic properties. Its chemical formula is usually expressed as Sm2Fe17N3. This material has the characteristics of high saturation magnetization intensity and high magnetocrystalline anisotropy field, showing unique advantages in the field of permanent magnet materials.

A brief discussion on the preparation and properties of rare earth nitrates

Rare earth nitrates are a class of compounds composed of rare earth elements and nitrate ions (NO3-). Their properties: Most rare earth nitrates are colorless crystals that are soluble in water; they have high thermal and chemical stability; rare earth nitrates are weakly acidic in solution; different rare earth ions will affect the color and fluorescence properties of rare earth nitrates. Their uses: Rare earth nitrates are widely used in the preparation of luminescent materials and fluorescent markers, such as phosphors, LEDs, liquid crystal displays, etc.; they are also used in the production of glass, ceramics and pigments to change the color and properties of materials; rare earth nitrates are also important raw materials for some catalysts and chemical reagents.

Preparation and market analysis of rare earth fluoride

Rare earth fluorides (also known as rare earth fluorides) are often used as molten salt components (molten salt electrolysis method) or raw materials (calcium thermal reduction method) in the smelting of single or mixed rare earth metals, as additives in the processing and manufacturing of non-ferrous metallurgy, special alloys, lubricants (agents), coatings, welding fluxes, permanent magnetic materials, etc., and as catalysts in organic synthesis.

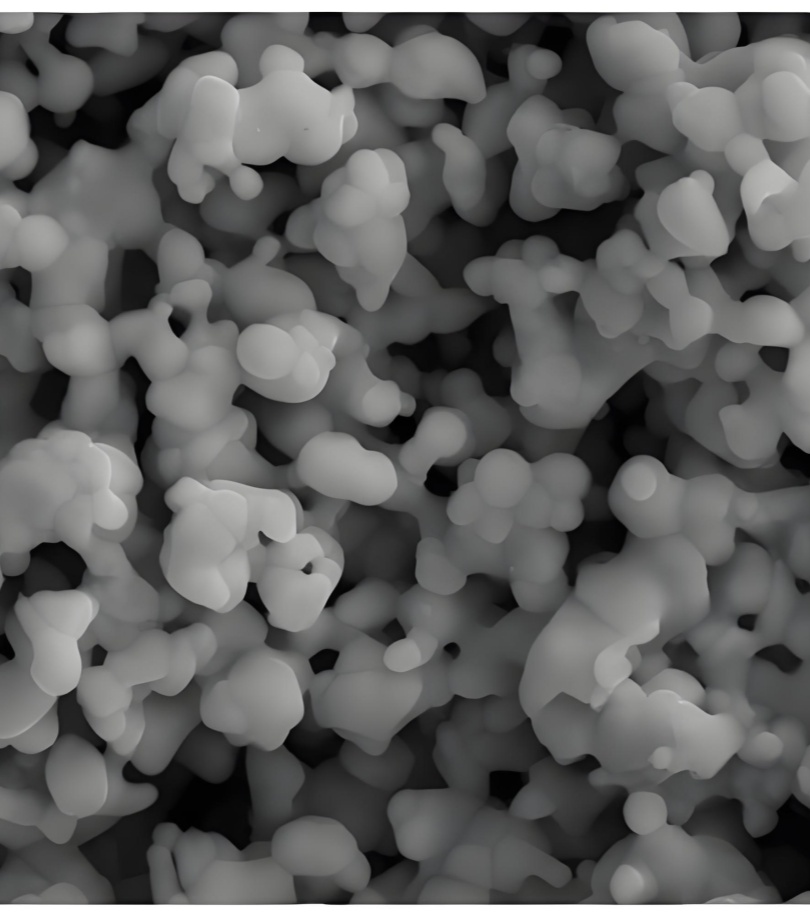

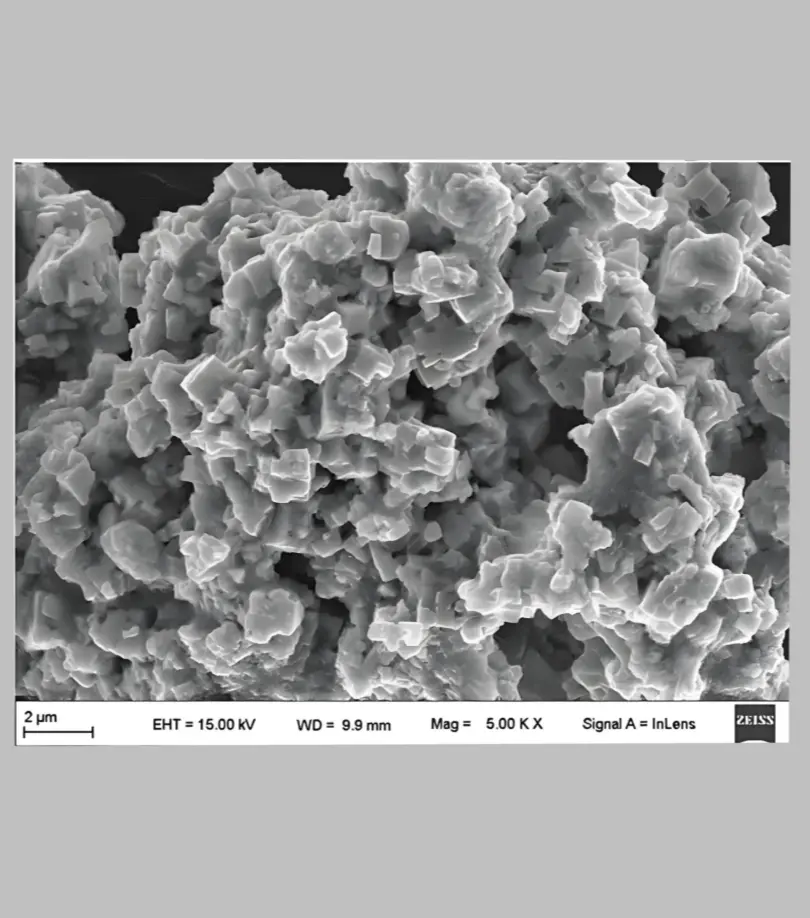

A Brief Discussion on the Research of Ultrafine Lanthanum Oxide Powder

Rare earth elements are known as a treasure trove of new materials and "industrial vitamins" due to their unique 4f electronic structure. Rare earth oxide powders are a hot spot in the current development of rare earth materials. Particle size distribution is a very important performance indicator of rare earth oxide powders, which affects the different application ranges of rare earth oxides.

A brief discussion on the properties and applications of rare earth fluoride oxides

Rare earth oxyfluorides have the advantages of rare earth oxides and rare earth fluorides, that is, rare earth oxyfluorides have lower phonon energy than rare earth oxides and better thermal stability and durability than rare earth fluorides. Currently, research on rare earth oxyfluorides has become a hot topic.

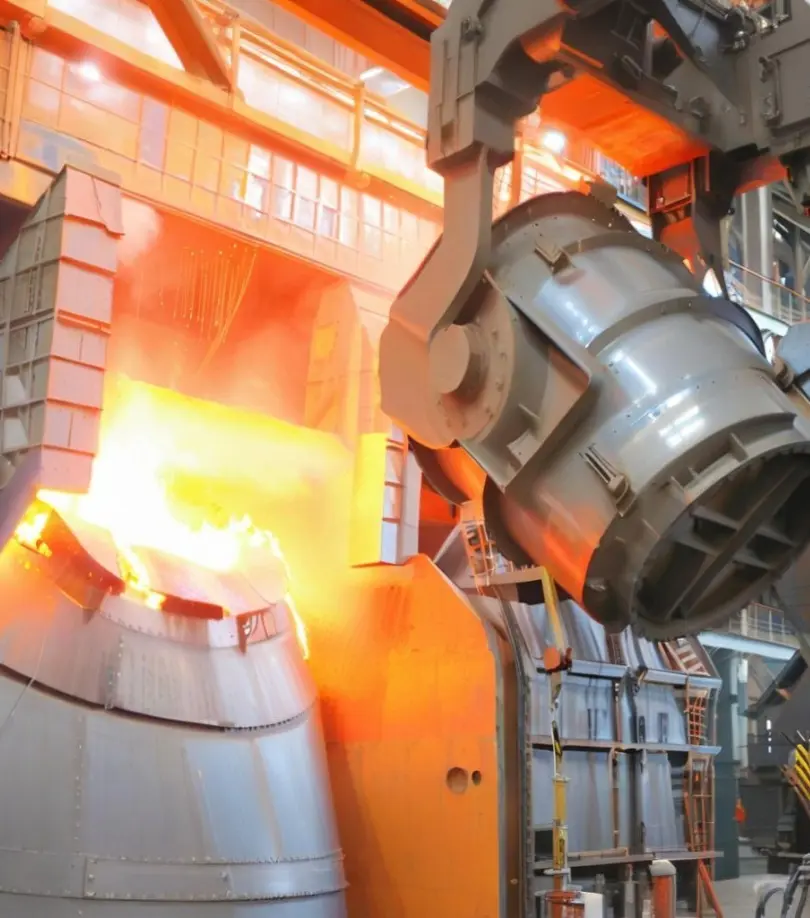

Application and Prospect of Rare Earth Magnesium Alloys

Magnesium and its alloys are known as "green engineering materials of the 21st century" because of their lightweight, biodegradable and recyclable characteristics. Magnesium alloys have excellent thermal conductivity, high specific strength and specific stiffness, good mechanical properties and recyclability. They have important applications and broad development prospects in the fields of national defense, military products, automobile production, electronic components, etc.

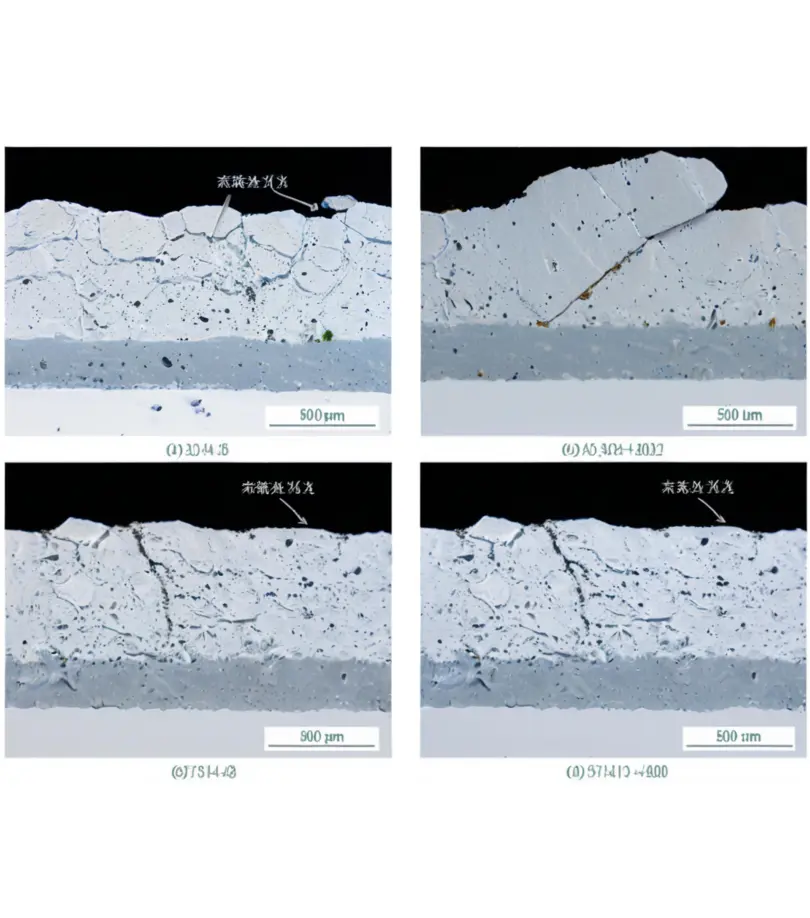

Application of rare earth in corrosion protection of aluminum alloy

Aluminum Alloy is relatively active. Under normal atmospheric conditions, an oxide film composed of α-Al2O3 and β-Al2O3 will naturally form on the surface, but the thickness is relatively thin. This makes the aluminum alloy matrix have a certain corrosion resistance in normal atmospheric environments, neutral and weak acid solutions. However, in environments with severe pollution, high humidity, coastal atmospheric environments, and other acidic and alkaline environments, the surface oxide film is difficult to have good corrosion resistance.