News

Application of rare earth oxide gadolinium oxide in uranium-containing pellets

With the increasing demand for economic efficiency in power plants, modern advanced reactors are developing towards large fuel loads, high burnup, and long cycles. This increase in initial fuel load significantly increases the initial residual reactivity of the reactor core within the active zone. In actual operation, separate burnable poison fuel assemblies alone are insufficient to maintain the required long-term reactor reactivity. However, integrated burnable poison fuel assemblies can improve the power distribution within the reactor core, thereby extending refueling cycles and improving fuel economy.

A Brief Discussion on the Preparation of Yttrium Oxide Transparent Ceramics

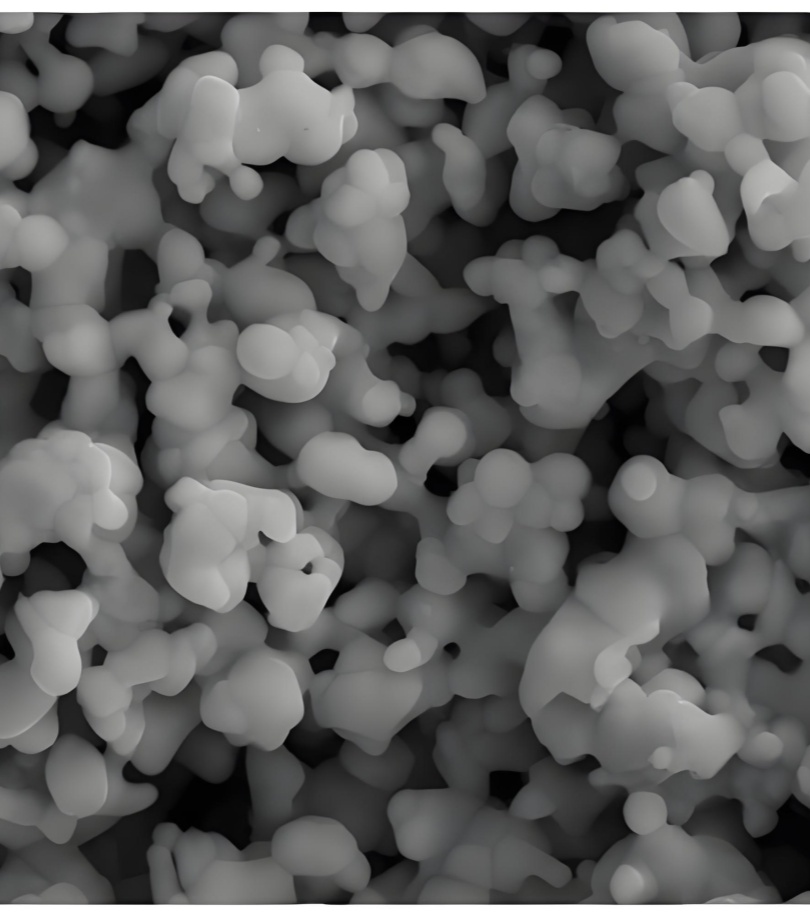

Yttrium Oxide (Y2O3) transparent ceramics have the characteristics of high melting point (2430 ℃), wide optical transparency range (200~8000 nm), excellent corrosion resistance and thermal stability, especially the low infrared emissivity and absorption coefficient exhibited in high temperature environment, which makes it stand out among many transparent ceramic materials and shows broad application prospects in many scenarios such as lasers, transparent windows and semiconductor devices.

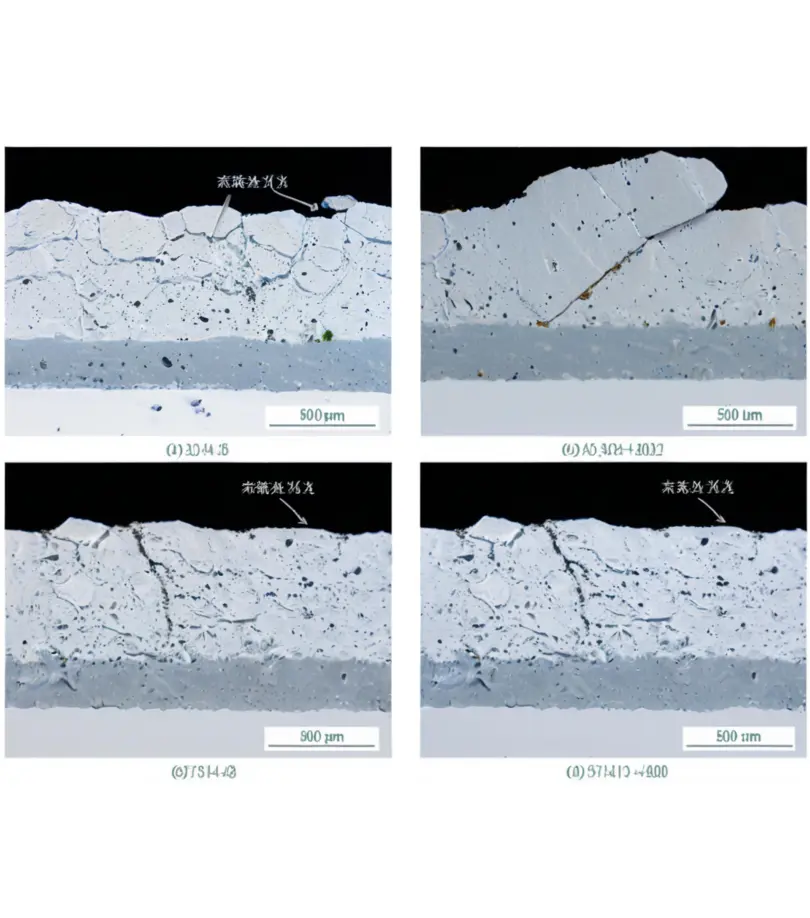

Research Progress of Yttria Coatings for Engineering Applications

Yttria coatings, as a key component of Rare Earth oxide coatings, offer wear resistance, high-temperature stability, and corrosion resistance, playing a vital role in key sectors such as aerospace, electronic communications, and the atomic energy industry. However, given the diverse service environments of engineering materials, traditional Y2O3 thermal barrier coatings are no longer able to meet these complex service requirements. These coatings exhibit poor coating stability, large failure areas, and significantly reduced service life, severely limiting their further adoption in engineering applications.

Research on rare earth flux in recycled aluminum industry

Aluminum and aluminum alloys have a series of advantages such as light weight, high strength, corrosion resistance and recyclability. They are widely used in building materials, decoration, aerospace, automation industry, etc. A large number of aluminum products can be recycled after reaching the end of their service life. Due to the mixture of various grades of aluminum alloys, scrap aluminum contains various impurities and pores. After remelting, the comprehensive mechanical properties of the recycled aluminum alloy are seriously affected and cannot reach the mechanical standards of original aluminum. Therefore, how to regenerate scrap aluminum and make its performance close to or reach that of original aluminum is currently a topic that needs to be studied urgently.

The role of rare earth in structural steel and its research progress

The atomic radius of rare earth is generally between 0.1821 and 0.2042 nm, while the atomic radius of iron is 0.1241 nm. The difference between the two is large, so the solid solubility of rare earth in steel is generally very low. A large number of studies have shown that the addition of trace rare earth elements can significantly improve the plasticity, toughness, wear resistance, heat resistance, corrosion resistance and many other properties of steel.

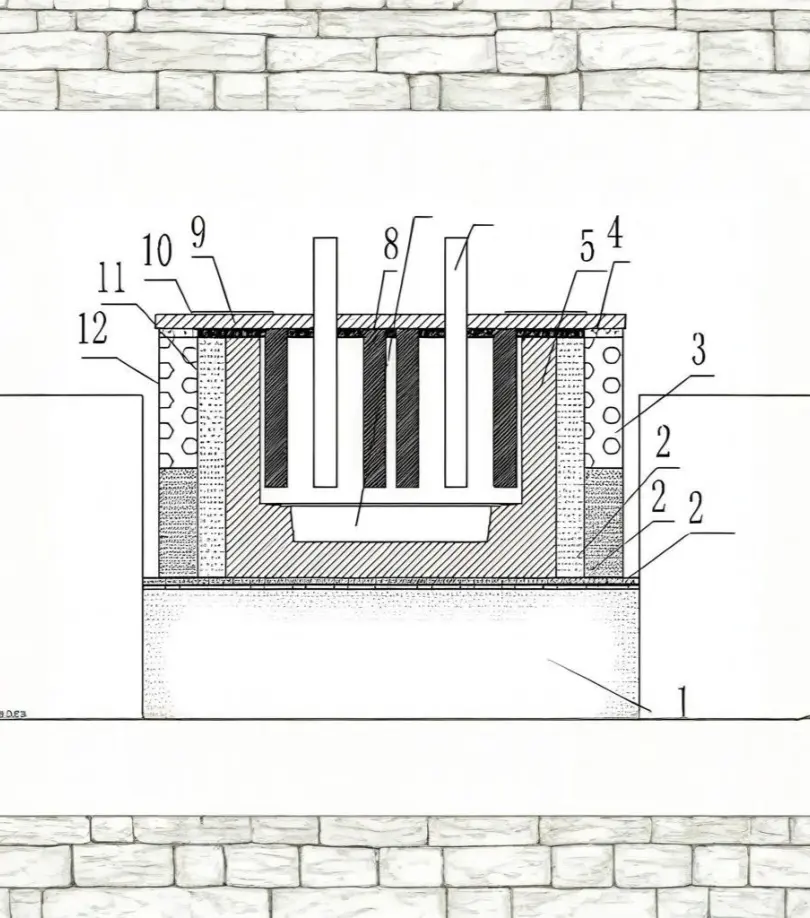

Research progress of rare earth molten salt electrolytes

Molten salt electrolysis is the main method for large-scale preparation of rare earth metals and their alloys, and it has the lowest cost, highest efficiency, and mature industrial application. Molten salt electrolyte is the main carrier in the electrolysis process, and the physical and chemical properties of the electrolyte are important factors affecting the quality of rare earth metals and the stability of the electrolysis process.

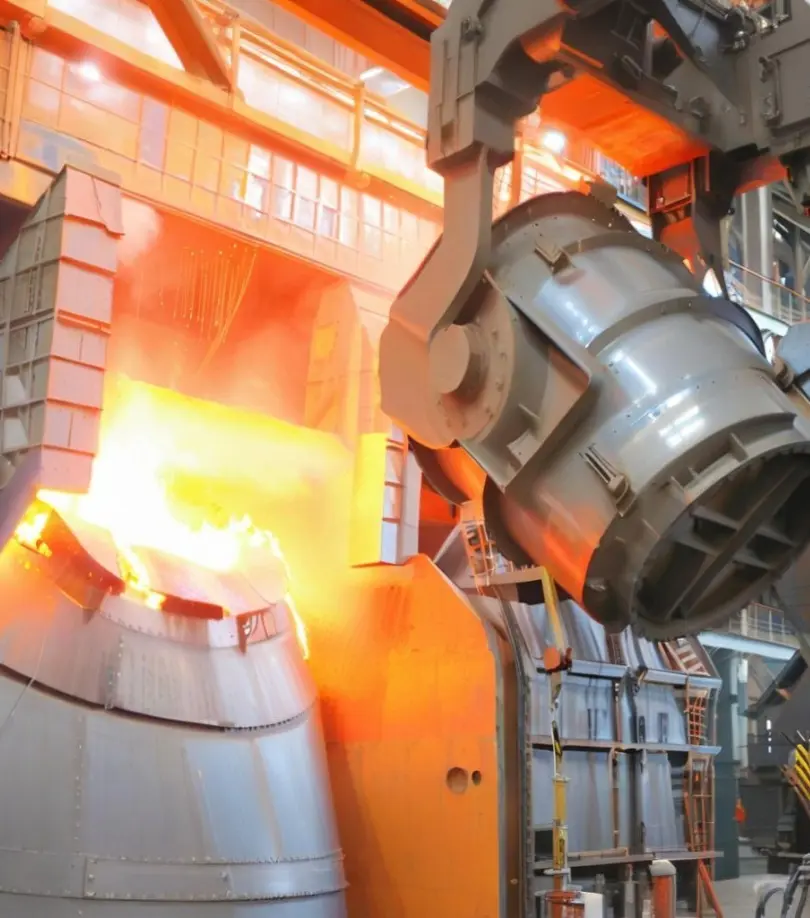

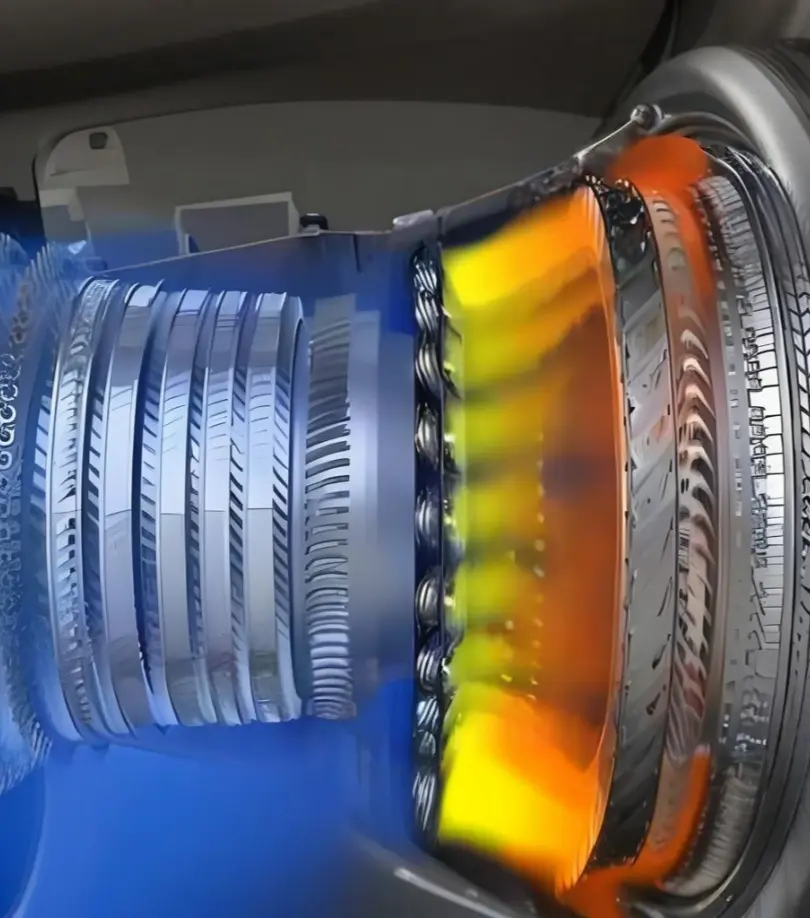

Research on rare earth oxide thermal barrier coatings

Gas turbines and aircraft engines are important power equipment. In order to improve output power and operating efficiency, gas turbines have been developing towards increasing turbine inlet temperature in recent years. At present, the turbine inlet temperature of ground-based gas turbines is above 1400℃, and the gas temperature of advanced military gas turbines is even 1500-1800℃. Such high temperatures make the operating environment of the hot end components of the gas turbine very harsh, and they need to withstand high-temperature oxidation, corrosion, airflow scouring, high-temperature creep and thermomechanical fatigue.

A brief discussion on the preparation process of yttrium nitride powder

Rare earth nitrides have a very high melting point (for example, the melting point of yttrium nitride reaches 2570℃) and are very stable at high temperatures. Yttrium nitride powder can be used in tantalum powder metallurgy to improve the processing properties of tantalum powder. It is also expected to be used in oxide and nitride high temperature ceramics.

A Brief Discussion on New Non-toxic Color Rare Earth Pigments

Due to the restrictions imposed by health and environmental regulations on the use of traditional heavy metal color pigments, Rhodia of France has successfully developed a new type of non-toxic color inorganic pigment based on rare earth element compounds. The company first launched a rare earth pigment based on cerium sulfide (Ce2S3), the product name is Neolor.

Since rare earth elements can successfully replace cadmium or lead, and play a key role in manufacturing pigments with excellent properties such as high hiding power, heat resistance, light resistance and prevention of warping of plastic products, and because they are non-toxic, rare earth pigments have been welcomed by users of plastics, coatings, ceramics, etc. as soon as they came out.

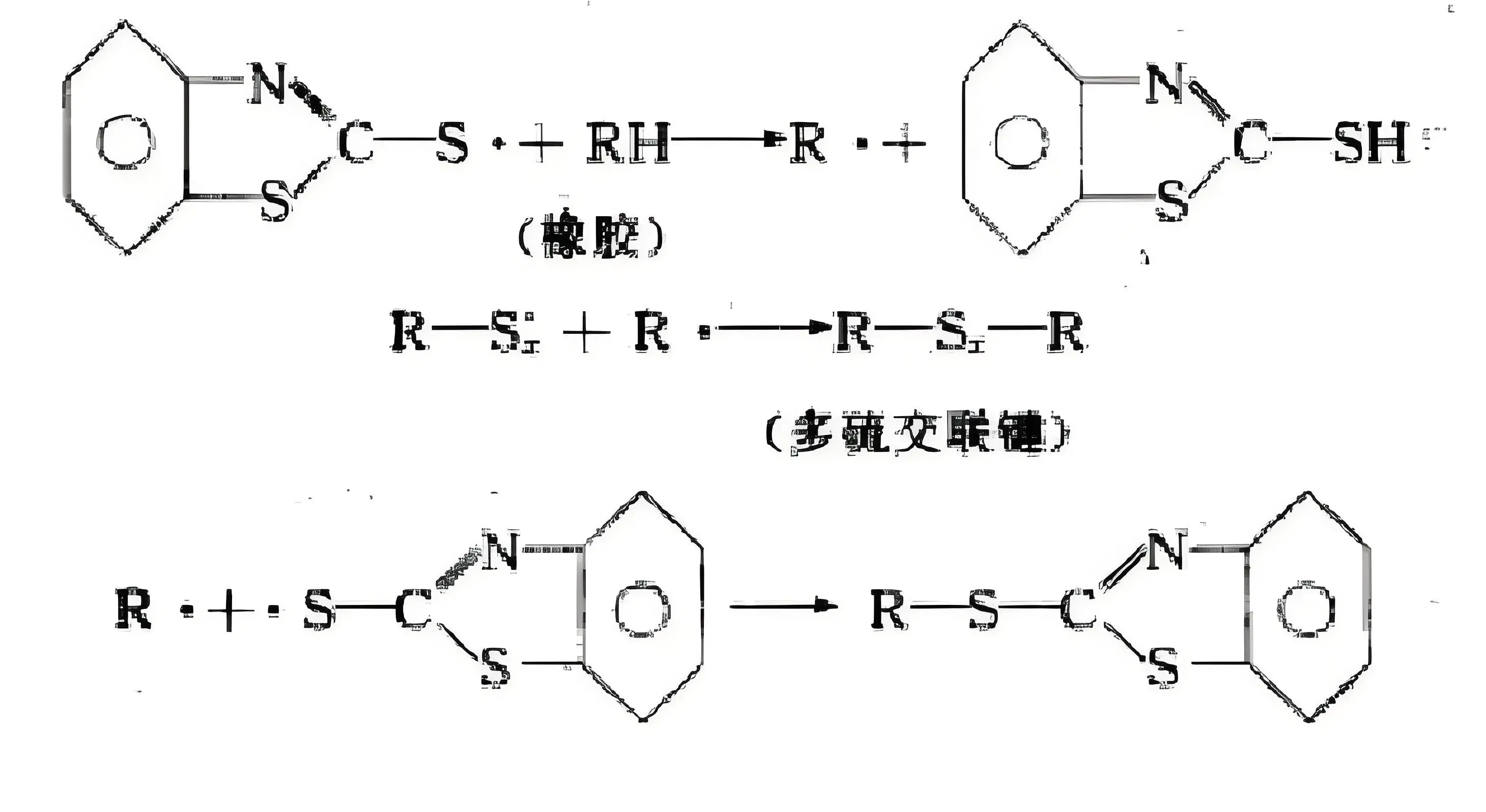

Application of rare earth sulfides in natural rubber

Natural rubber (NR) has a complex composition. In addition to the main component cis-1,4-polyisoprene, it also contains a small amount of non-rubber substances such as protein, fatty acids and ash. NR has excellent properties, not only good elasticity and crack growth resistance, but also low heat generation and hysteresis. Therefore, NR is widely used in many fields such as tires, hoses, sports equipment, and aircraft and automobile parts due to its excellent comprehensive performance, and plays an indispensable and important role in the national economy and national defense construction.